Thermal Management for Maximum Performance

Various cooling solutions are available to address the thermal management needs of electronic equipment. The choice of cooling method depends on factors such as available space, environmental conditions, and cost.

Thermal Management Solutions for Electronic Equipment

In today’s fast-paced and high-demand environment, electrical equipment is constantly pushed to its limits, generating significant heat.

Overheating can cause components to degrade faster, increasing maintenance costs and downtime. To address this challenge, companies must prioritize implementing robust thermal management solutions that effectively dissipate heat and maintain optimal operating temperatures.

Effective thermal management is not without its challenges. One of the most common challenges is limited space within electrical equipment enclosures. As technology evolves, equipment becomes more compact, leaving little room for traditional cooling methods.

Another challenge is the increasing power density of electrical equipment. Higher power densities generate more heat in a smaller space, making dissipating more difficult. This requires innovative cooling solutions that can handle the higher heat loads without compromising performance.

Additionally, environmental factors such as ambient temperature, humidity, and dust can impact the performance of cooling systems. These factors must be considered when designing and implementing thermal management solutions to ensure optimal performance and longevity of electronic equipment.

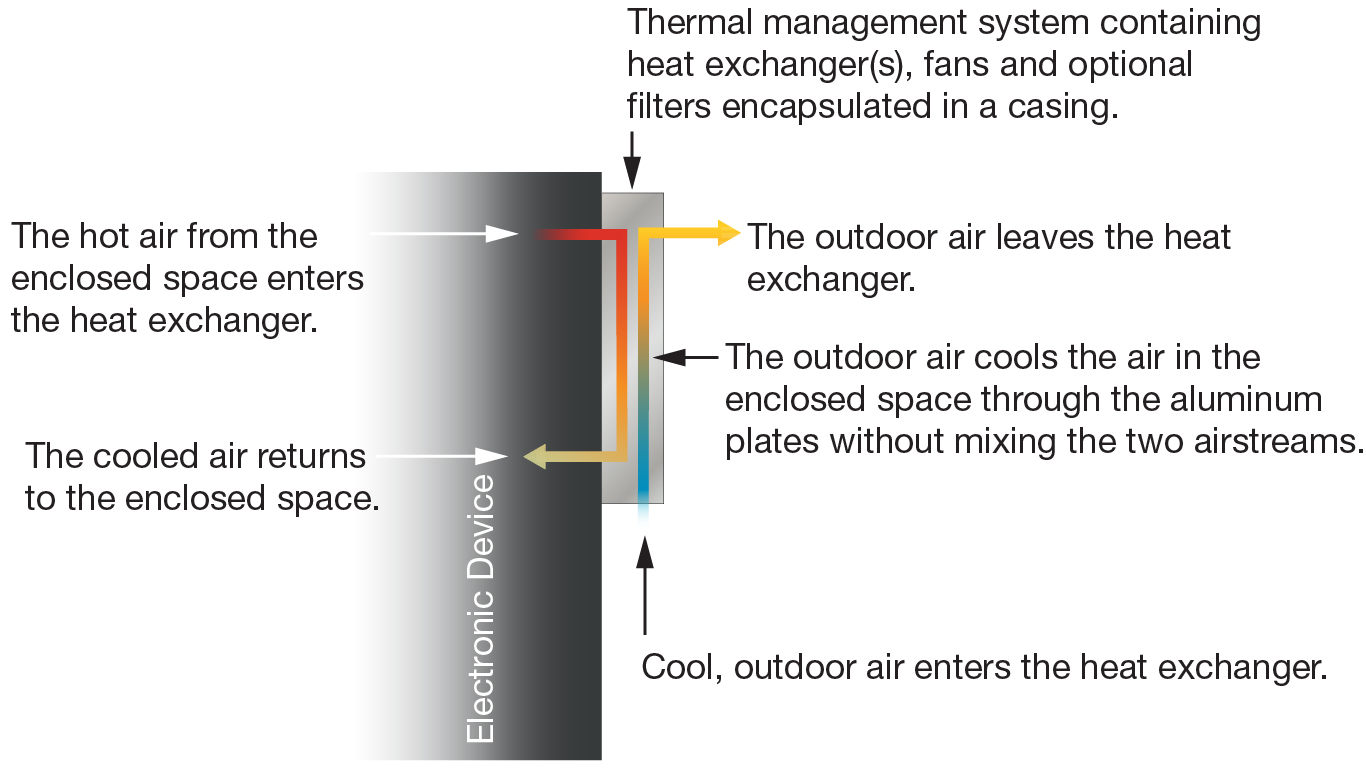

Heatex offers two types of plate heat exchangers suitable for thermal management solutions: crossflow and counterflow.

In a crossflow exchanger, the cold and the warm air flow perpendicular to each other. In a counterflow exchanger, the two airstreams flow in opposite directions. The application determines which heat exchanger type provides the best solution.

- Thanks to a simple but robust design, air-to-air heat exchangers require very low maintenance.

- Using natural heat flux in combination with high-performance design keeps running costs low.

- The electronic equipment is protected from water and dust by separating the two air flows.

- Air-to-air heat exchangers are flexible and easy to design and implement using air as a cooling medium.

Recommended Products for Thermal Management

The Most Efficient

Model H2 is our most efficient crossflow plate heat exchanger. It combines low weight with high differential pressure resistance and can reach typical dry temperature efficiencies above 80%.

Heatx Crossflow Heat Exchangers

Slim and Versatile

Model M is a lightweight counterflow exchanger specifically developed for thermal management. It offers customizable aspect ratios and multiple flow path configurations. It’s manufactured of aluminum with Aluzinc steel casings.

Heatex Counterflow Heat ExchangersCase Study

DEC builds synchronous condensers to stabilize the electrical grid. They require cooling to operate effectively. Heatex provides a thermal management solution based on plate heat exchangers.

Read Case Study

Proven Technology

Thousands of Heatex plate heat exchangers are operating in enclosures all over the world.

Solid Track Record

Many years of experience supplying plate heat exchangers for electronic cooling applications.

Extensive Capabilities

With production facilities in Europe, the US and China we are always close and accessible.