Complete Wind Turbine Cooling Systems

The heat generated by energy conversion and solar radiation needs to dissipate to ensure the life expectancy of the components inside the nacelle. Heatex develops complete and customized wind turbine cooling systems.

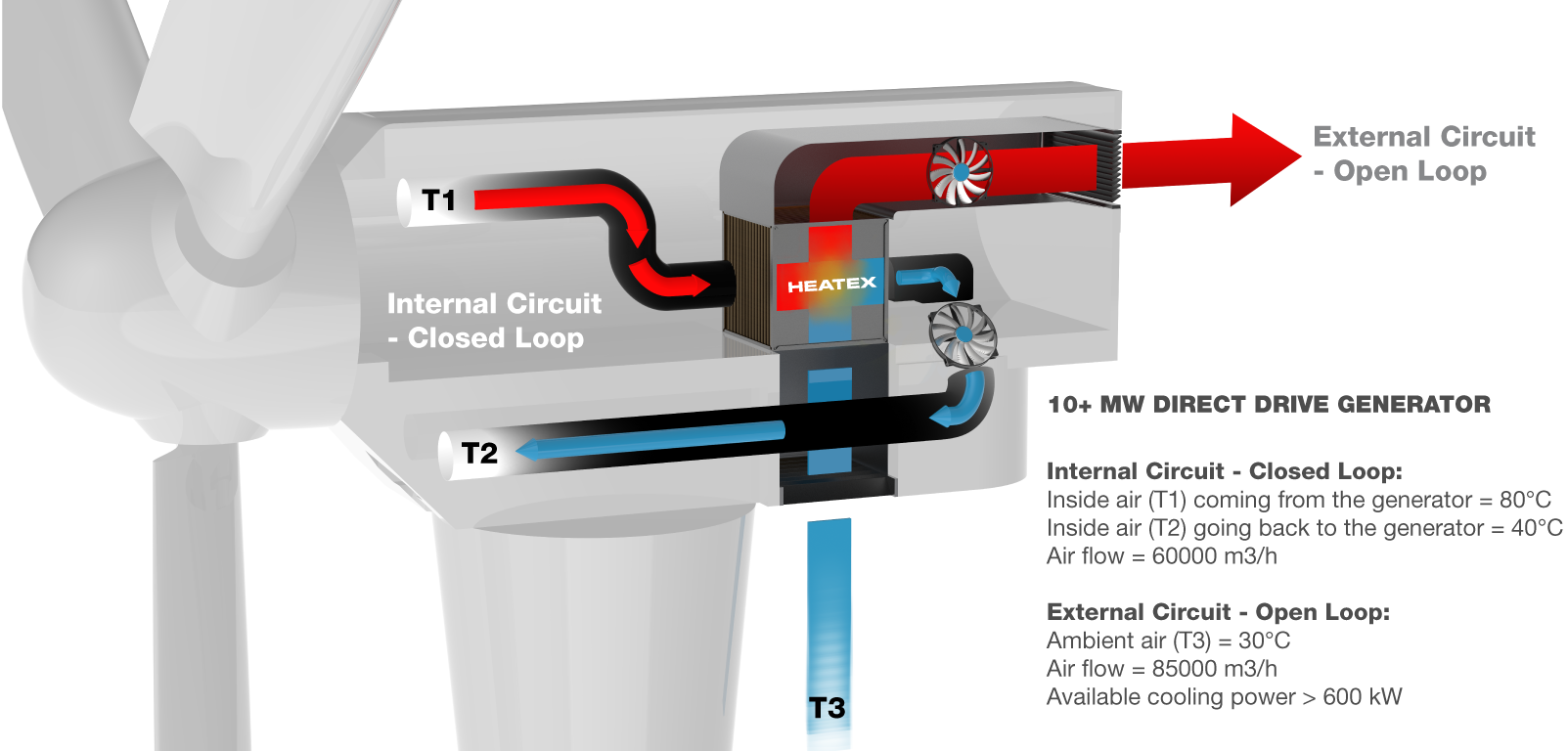

Generator Cooling

Customized solutions with proven performance for all types of turbines.

Nacelle Cooling

Complete cooling systems with flexible design to meet space and performance requirements.

Converter/ Transformer Cooling

Closed loop solutions for efficient and reliable cooling of sensitive electronic equipment.

GE Haliade-X

GE Renewable Energy’s Haliade-X, one of the most powerful wind turbines in the world, is cooled by a Heatex custom-made closed-loop cooling system.

CSIC HZ windpower’s 10MW

CSIC HZ Windpower’s 10MW H210-10.0 turbine is now in full serial production and operating outside the coast of Shandong in China.

| Main Challenges for Wind Turbine Cooling | Heatex Solutions | |

| Secure stable AEP and reduce LCOE | State of the art heat exchanger for high cooling efficiency and optimized system design for low power consumption. | |

| Minimize downtime and failure rates | Proven system design with low complexity, few moving components and built-in redundancy. | |

| Minimize installation cost | Customized design with careful consideration to weight and space requirements. | |

| Minimize maintenance cost | Heat exchanger with self-cleaning capability providing full protection of internal air from salt, sand and dust. | |

| Maximize lifetime | Corrosion protection with very high durability for all types of environment, including offshore. | |

This Is How It Works

When converting between different forms of energy, a part of the available energy is lost, often as heat. In a wind turbine, kinetic energy is converted to electrical energy and the losses are transferred into heat. Generally, larger generators create more heat than smaller versions.

Heatex Air-to-Air Heat Exchangers

In an air-to-air heat exchanger, the outside air passes through the plate heat exchanger on one side of the plate and the air from the nacelle recirculates on the other side. The air coming from the inside of the nacelle is cooled by the outside air through thin aluminium plates.

The outside air, contaminated with salinity, humidity and dust, and the clean dry inside air never mix, creating a closed-loop system and a desirable environment for the electronic components inside the nacelle.

The heat exchanging process depends on differences in temperature between the supply (inside) air and the exhaust (outside) air. Higher differences between these flows require less fan power to transfer the same amount of heat.

To save energy even further, it’s possible to install a VFD, Variable Frequency Drive.

Ask an Expert

Together with our certified APQP4Wind Specialists, our mission is to provide high-performance wind turbine cooling systems, enabling the wind industry to produce the best, most efficient generators.

All systems are fully customized to optimize the operation and fulfill manufacturer requirements. Contact our experts for technical expertise.

Heatex vs Other Wind Turbine Cooling Systems

Heatex offers a cooling system that combines the positive aspects of traditional cooling methods while minimizing the drawbacks of filtered air and liquid-to-air solutions. Heatex air-to-air cooling systems are suitable for both onshore and offshore applications and allow for a high degree of flexibility, which makes it possible to retrofit Heatex cooling solutions into existing wind turbine generators.

| Cooling Technology | Maintenance Cost | Power Consumption | Cooling Capacity | Cooling Efficiency | ||||

| Air/Liquid | Complex systems with more components subjected to regular maintenance. | Moderate power consumption and operating cost. | Large systems with high capacity are possible. | High cooling capability with liquids but multiple heat exchangers in systems reduce the overall efficiency. | ||||

| Filtered Air | Filters must be replaced with regular intervals. Very costly offshore. | Low power consumption and operating cost. | High capacity is possible but proof of concept for offshore is not given. | The temperature of ambient air can be utilized for cooling. | ||||

| Heatex Air/Air Solutions |

Self-cleaning heat exchanger and less complex system with minimal maintenance. | Moderate power consumption and operating cost. | Large systems with high capacity are possible. | The temperature of ambient air might not be fully utilized but high efficiency can be achieved with optimized heat exchangers. | ||||

Proven Technology

Over 2000 Heatex cooling systems are successfully operating worldwide.

Solid Track Record

Heatex has over 10 years of experience in both On- and Offshore applications.

Extensive Capabilities

We are delivering cooling systems to double-digit projects all around the world.