Energy Efficient Wood Drying

The challenges that arise in wood drying (boards) are diverse. However, air-to-air heat exchangers are customizable to fit any wood drying application, and the payback period is usually less than 1 year.

Wood Drying Challenges & Solutions

Wood drying requires considerable energy to evaporate the large volume of water held in the wood. Whether it is a conventional batch kiln or a top-of-the-class continuous drying kiln, all have challenges.

Heatex heat exchangers are easy to configure in size and material to fit most environments and wood drying systems. All our models save sufficient energy to provide short amortization periods and valuable savings even in corrosive and heavily polluted environments.

Energy Efficiency Wood Drying

Thermal energy is the main cost for a wood dryer and dramatically impacts the economy. Therefore, a heat recovery system can significantly improve the operating cost. The combination of high humidity and high particle content in the air must be carefully considered when designing and optimizing the heat recovery system. Our product selection tool, Heatex Select, enables such optimization.

Solutions

- Using optimized crossflow heat exchangers such as Model H2, H, or Z

- Calculating the performance requirements accurately

- Designing and optimizing the heat exchanger according to the application demands

Corrosive Environments

Substances from the wet wood often result in a corrosive environment. Proper material selection is critical to avoid failure and frequent replacement of equipment.

Solutions

- Choosing a heat exchanger with either complete aluminum or stainless steel materials

- Adding an epoxy coating to the heat exchanger plates

Wood Particles in the Air Stream

Various particles and debris from the wood are mixed into the air stream, increasing the risk of clogging the heat recovery system with reduced performance.

Solution

- Optimizing plate distances to prevent clogging (Heatex offers up to 12 mm (0.43″) plate distances) while ensuring the best efficiency possible.

Recommended Products for Wood Drying

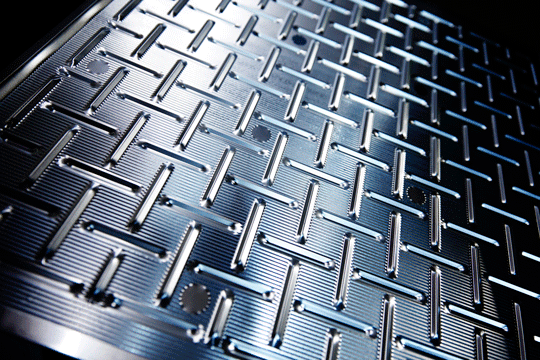

Heatex Model H2 & H

Heatex crossflow models H2 and H should be configured with aluminum heat transfer plates and framework (profiles and end plates). Additionally, we offer a wide range of configurations and options, such as:

- Epoxy-coated heat transfer plates

- Plates distances between 1.6 – 12 mm (0.06″- 0.47″) (depending on the model)

- Sizes between 200 – 3000 mm (7.87″ – 118.1″) (depending on the model)

- Max. differential pressure between 1800 – 3000 Pa (depending on plate distances and model)

Heatex Model Z

Heatex crossflow model Z is entirely stainless steel and suitable for the toughest wood drying applications.

- Plate distances between 6 – 9 mm (0.24″ – 0.35″)

- Sizes between 600 – 2400 mm (23.62″ – 94.49″)

- Max. differential pressure up to 4000 Pa (depending on plate distance)

Payback Example

Implementing a heat exchanger to recover waste energy is always a good investment. In this example, the payback period (return on investment) will be less than a year!

This calculation is based on:

- 50 kW heat recovery system (CAPEX 4000 € )

- 90% heat conversion efficiency

- 3000 h / year operating time

- 0.64 MWh / m3 energy content (sawdust)

- 20 € / m3 fuel cost (sawdust)

| Equivalent fuel power (Heat recovery/heat conversion efficiency) |

50 kW / 90% = 56 kW | |||||

| Fuel energy saving (Equivalent fuel power x operating hours) |

56 kW x 3000 h = 167 MWh | |||||

| Total amount of fuel saved (Fuel energy saving/energy content) |

167 / 0.64 = 260 m3 | |||||

| Total fuel saving (Total amount fuel x fuel cost) |

260 x 20 € = 5 200 € | |||||

| Payback (CAPEX / total fuel saving) |

4000 € / 5200 € = < 1 year | |||||

Case Study

The company has been in the business of drying wood for over 40 years and is today an international leader in the field. The solution is based on a Heatex crossflow plate heat exchanger and is fitted in a heat recovery module placed on the roof of the kiln.

Read Case Study