New Heatex Select

We have released a new version of Heatex Select. This update features new functionality, general improvements, and bug fixes.In this release, we have significantly improved the experience for professional users by adding a “Fullscreen” mode. Additionally, we have added functionality for indirect adiabatic cooling calculation and a new option for increased water and air tightness, “AquaSeal”.

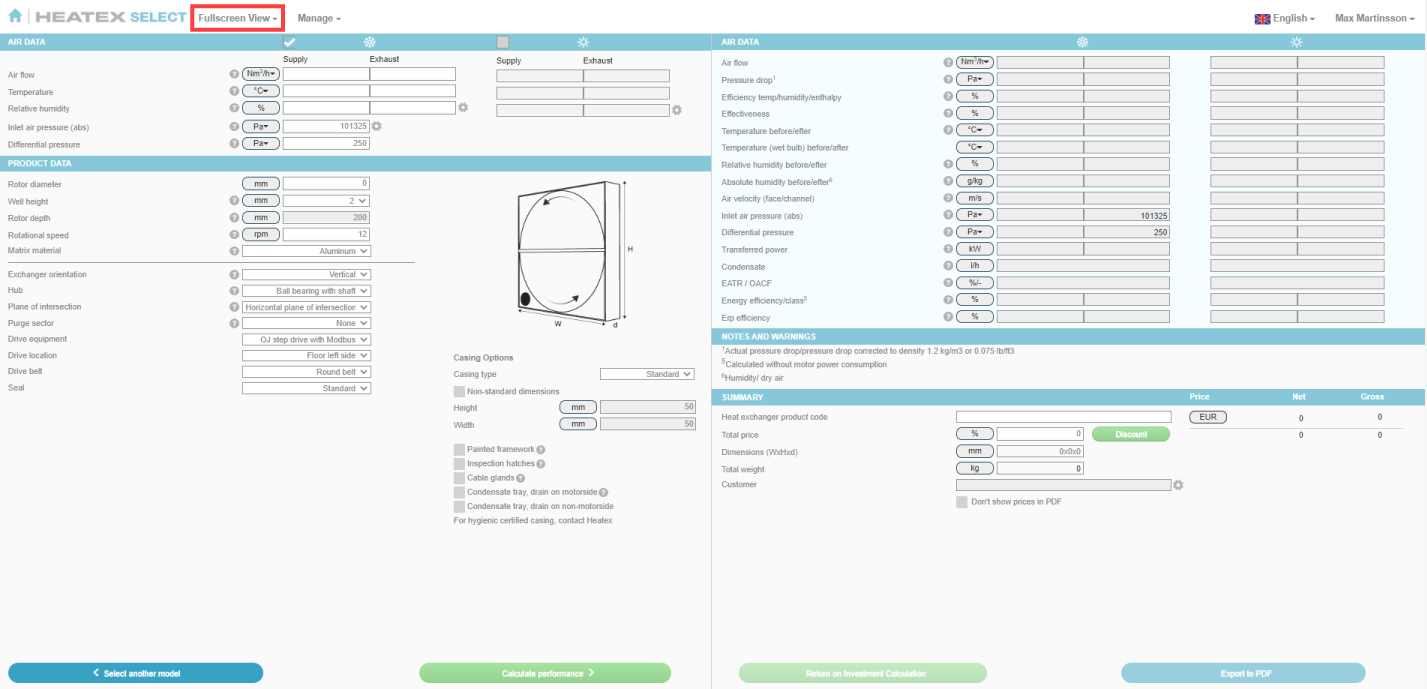

Fullscreen View

By choosing “Fullscreen View” in the drop-down menu, you’ll switch from a step-by-step process to an all-in-one mode. By gathering all inputs and outputs on one page, the number of steps needed to complete a calculation is significantly reduced.

It might be intimidating for an inexperienced user, but it makes calculating quicker for frequent users, especially if you have to iterate a lot. However, we’ll keep the “Classic View” alongside the “Fullscreen View” and leave it up to you to decide what version you like best.

Indirect Adiabatic Cooling

Adiabatic cooling is a well-established method of enhancing air cooling by applying water. Indirect adiabatic cooling means applying water to the secondary air stream (often the ambient air), cooling it down and thus improving the cooling of the primary air stream.

One example is data center cooling, where the primary air consists of the circulating data center air, and the secondary air stream consists of ambient air.

The benefit of indirect cooling is that no extra humidity is added to the primary circuit, in addition to improved heat transfer.

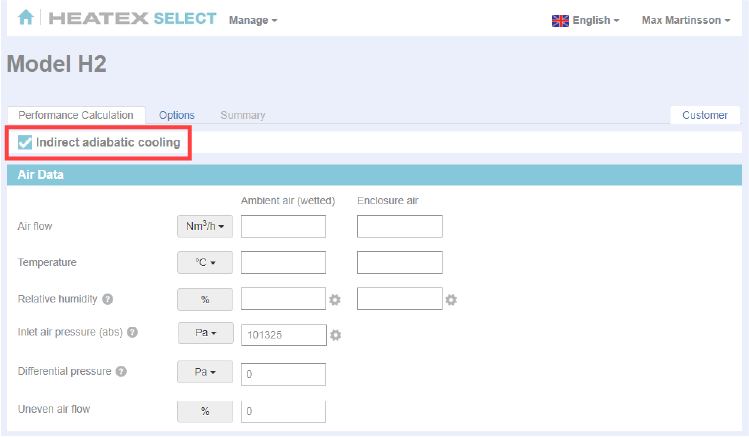

Indirect adiabatic cooling applications require a particular calculation that simulates the process of applying water to the secondary circuit. Heatex Select allows calculation with spray nozzles or a wet pad.

Additional functionality is a 2-step configurator where water is applied in two positions, at the inlet and in the middle of the heat exchanger setup.

You can calculate the performance of an indirect adiabatic cooling configuration in Heatex Select Online (Model H2 and Model H only) by checking the box “Indirect adiabatic cooling.

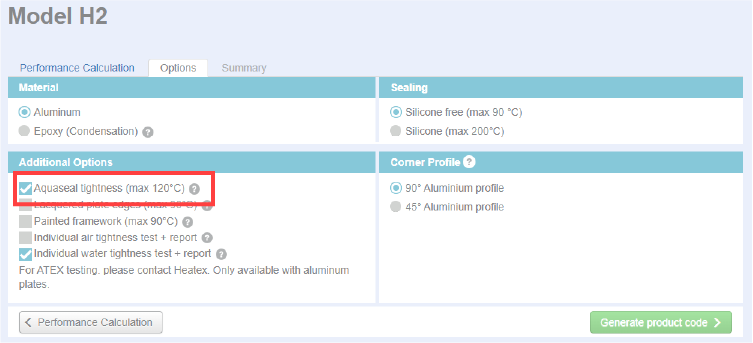

AquaSeal

For water tightness and an even higher level of air tightness, Heatex offers AquaSeal, a process used to fill all plate crevices with a special polymer. This will result in a heat exchanger suitable for high-pressure or direct water spray applications, such as swimming pool applications, electronic cooling, adiabatic cooling, etc.

The tightness is guaranteed if a specially developed water leakage test is conducted. The test is then conducted on every heat exchanger applied with AquaSeal. AquaSeal is available on heat exchangers with plate spacing larger than 4mm (0.16″).