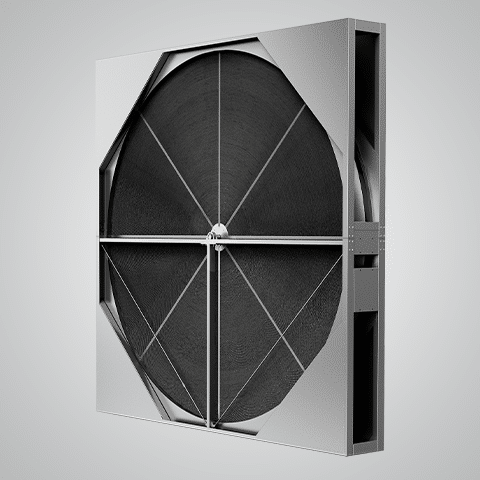

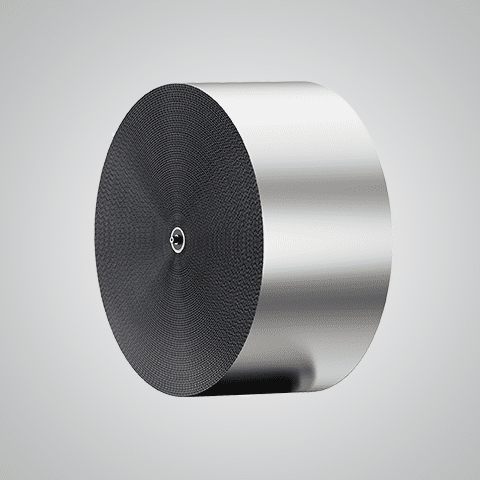

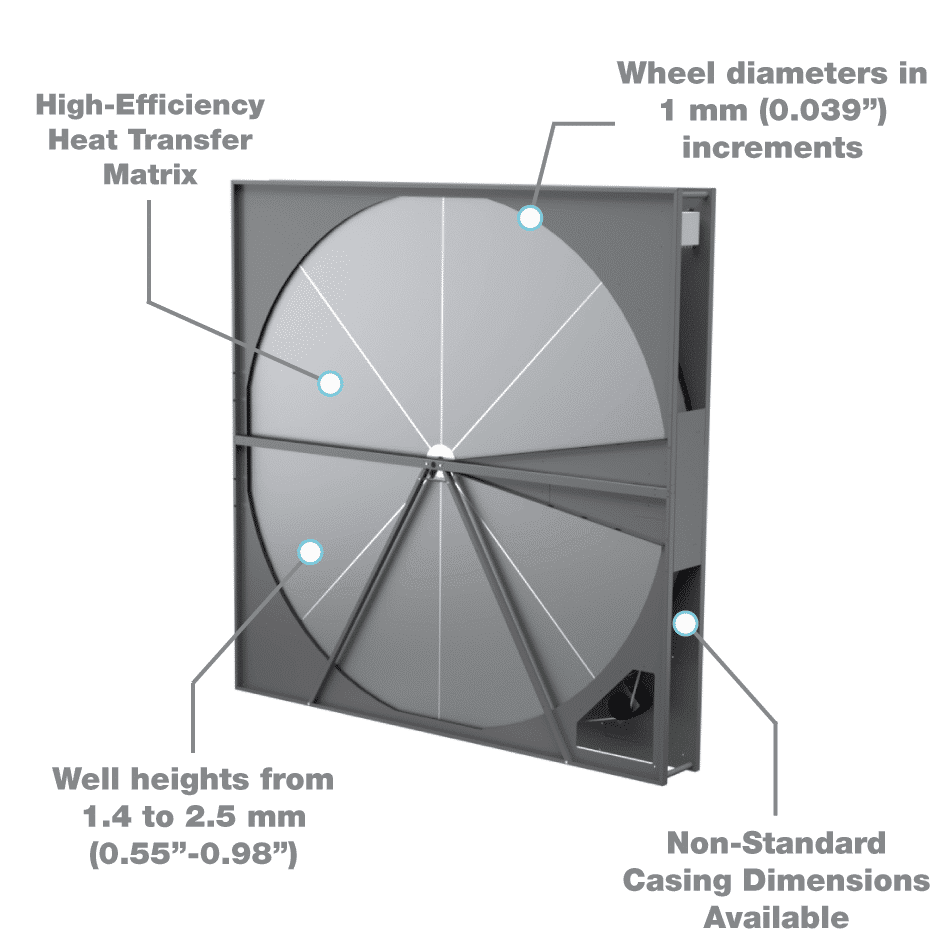

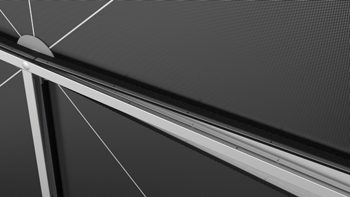

The wheel is built up by a matrix that consists of two foils, one flat and one corrugated; together, they create channels for the air to pass through. The wheel is rotated by an electric motor and belt drive system.

In one half of the rotation, the exhaust air from the inside space flows through the matrix. Its heat is stored in the matrix, and in the other half of the rotation, it is transferred to the fresh supply air from outside.

The size of the channel is called well height. Different well heights and diameters of the wheel give different efficiencies, pressure drops, and airflow rates.

Rotary heat exchangers that are properly constructed, installed, and maintained have almost zero transfer of particle-bound pollutants.